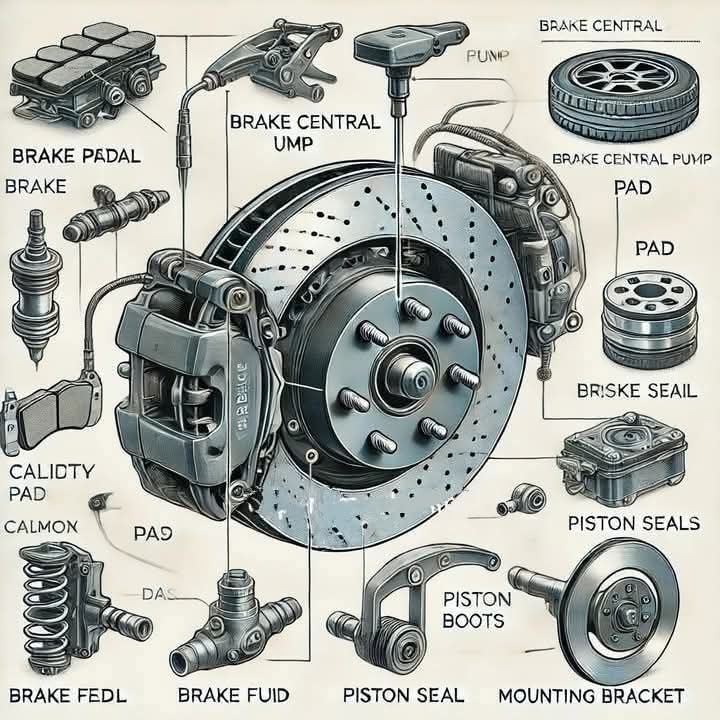

a brake system, likely for a car. Here's a breakdown of the labeled components:

Main Components:

* Brake Pedal: The driver applies pressure to this pedal to initiate braking.

* Brake Central Pump: This is the heart of the hydraulic braking system. It converts the mechanical pressure from the pedal into hydraulic pressure.

* Brake Pad: These friction pads are mounted on the caliper and press against the brake rotor to slow down the vehicle.

* Brake Rotor: A metal disc that rotates with the wheel. The brake pads clamp onto it to create friction and slow down the wheel.

* Caliper: A housing that holds the brake pads and applies pressure to them against the rotor.

* Piston: Located within the caliper, these push the brake pads against the rotor when hydraulic pressure is applied.

* Piston Seals: These prevent brake fluid from leaking past the piston.

* Piston Boots: These protect the piston seals from dirt and debris.

* Brake Fluid: This incompressible fluid transmits pressure from the master cylinder to the calipers.

* Brake Field: This likely refers to the area where the brake system operates, such as the wheels or the brake lines.

* Mounting Bracket: This attaches the caliper to the vehicle's suspension.

Other Components:

* Brisk Seal: This is likely a type of seal used in the brake system.

* Calidity Calmon: This might refer to a type of brake pad material or a brand.

Overall, the image provides a comprehensive view of the key components involved in a typical hydraulic brake system and how they work together to slow down and stop a vehicle.

#automotive #mechaniclife #cars #mechanical #mechanic #carparts #restoration #viral #carmemes #usa

#fypシ #autos #automobile #mechanic #mechanical #engineering #cars #engine #sensors #usa #australia

Main Components:

* Brake Pedal: The driver applies pressure to this pedal to initiate braking.

* Brake Central Pump: This is the heart of the hydraulic braking system. It converts the mechanical pressure from the pedal into hydraulic pressure.

* Brake Pad: These friction pads are mounted on the caliper and press against the brake rotor to slow down the vehicle.

* Brake Rotor: A metal disc that rotates with the wheel. The brake pads clamp onto it to create friction and slow down the wheel.

* Caliper: A housing that holds the brake pads and applies pressure to them against the rotor.

* Piston: Located within the caliper, these push the brake pads against the rotor when hydraulic pressure is applied.

* Piston Seals: These prevent brake fluid from leaking past the piston.

* Piston Boots: These protect the piston seals from dirt and debris.

* Brake Fluid: This incompressible fluid transmits pressure from the master cylinder to the calipers.

* Brake Field: This likely refers to the area where the brake system operates, such as the wheels or the brake lines.

* Mounting Bracket: This attaches the caliper to the vehicle's suspension.

Other Components:

* Brisk Seal: This is likely a type of seal used in the brake system.

* Calidity Calmon: This might refer to a type of brake pad material or a brand.

Overall, the image provides a comprehensive view of the key components involved in a typical hydraulic brake system and how they work together to slow down and stop a vehicle.

#automotive #mechaniclife #cars #mechanical #mechanic #carparts #restoration #viral #carmemes #usa

#fypシ #autos #automobile #mechanic #mechanical #engineering #cars #engine #sensors #usa #australia

a brake system, likely for a car. Here's a breakdown of the labeled components:

Main Components:

* Brake Pedal: The driver applies pressure to this pedal to initiate braking.

* Brake Central Pump: This is the heart of the hydraulic braking system. It converts the mechanical pressure from the pedal into hydraulic pressure.

* Brake Pad: These friction pads are mounted on the caliper and press against the brake rotor to slow down the vehicle.

* Brake Rotor: A metal disc that rotates with the wheel. The brake pads clamp onto it to create friction and slow down the wheel.

* Caliper: A housing that holds the brake pads and applies pressure to them against the rotor.

* Piston: Located within the caliper, these push the brake pads against the rotor when hydraulic pressure is applied.

* Piston Seals: These prevent brake fluid from leaking past the piston.

* Piston Boots: These protect the piston seals from dirt and debris.

* Brake Fluid: This incompressible fluid transmits pressure from the master cylinder to the calipers.

* Brake Field: This likely refers to the area where the brake system operates, such as the wheels or the brake lines.

* Mounting Bracket: This attaches the caliper to the vehicle's suspension.

Other Components:

* Brisk Seal: This is likely a type of seal used in the brake system.

* Calidity Calmon: This might refer to a type of brake pad material or a brand.

Overall, the image provides a comprehensive view of the key components involved in a typical hydraulic brake system and how they work together to slow down and stop a vehicle.

#automotive #mechaniclife #cars #mechanical #mechanic #carparts #restoration #viral #carmemes #usa

#fypシ #autos #automobile #mechanic #mechanical #engineering #cars #engine #sensors #usa #australia

0 Commentarii

0 Distribuiri